We concluded in the previous post that a still designed for whiskey making should be efficient and have a rather narrow column. In still design the challenge is to manage the distillation process in such a way that affordable predictable and repeatable outcomes in terms of spirit quality and quantity are achieved.

Reflux Still Management Operation Moonshine Stills Distillery Equipment

It is a factor and has no units.

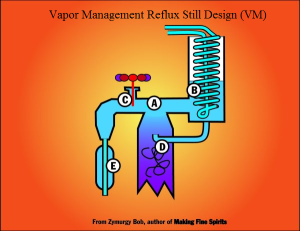

. Vapor phase reflow or condensation reflow soldering uses a liquid that has a high boiling temperature. Vapor diffusion is another source of moisture for the building enclosure and a vapor barrier or vapor retarder is sometimes used to control diffusion and potential condensation. Some vapor goes directly to the reflux condenser B and some goes to the gate valve C.

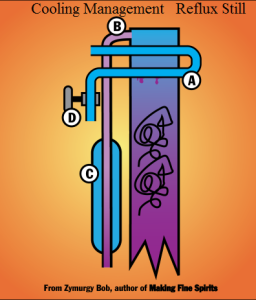

In a vapor management reflux still the vapor travels up the packed column where it is divided at point A. Water boils at 100 C at sea level and turns into vapor steam. A Still using cooling management design has a reflux condenser A before the take off port B.

Environmental management UTILISATION OF VAPOUR COMPRESSION. If I feed cold water to the top offset condenserfully open the reflux valve. The efficiency of the still makes it possible to use power management as an effective means to influence vapour speeds even more.

Vapour resistance factor also known as th µ-value which is the resistivity of a material relative to that of still air. Air Water and Vapor Barriers. 1212 Vapour dispersion system means a vapour processing unit which releases cargo vapour to the atmosphere through a venting system not located on the tanker being loaded or ballasted.

This condenser is usually in the column of the still and reflux is controlled by a water valve D hence the cooling management design. N actual N theory e 11 Step 6. As Building Regulations are demanding ever higher thermal efficiency in both commercial and domestic sectors todays building professional increasingly needs to consider air tightness as a way of improving the thermal performance of the building envelope not simply adding more insulation.

The narrow column creates the vapour speeds needed to carry over early Tails. The State of New Jersey its agencies and employees assume no responsibility to any person or entity for the use of this information. The total pressure is still atmospheric.

A design guideline that should be used is that the height of the column should not be higher than 175 feet. Principal Dimensions of the Column DiameterHeight. For design purposes a value of 80 to 85 per cent of the flooding velocity should be used.

Next in the process preheaters and several column stages there are typically six to eight columns for todays energy-efficiency requirements vaporize pure steam and generate WFI. Height-to-diameter ratio should be less than 20 to 30. The vapor at the reflux condenser is condensed and the liquid is sent back down to the column in tube D.

An example of this design is this CM. When designing one intends to make a structural solution for a problem or challenge that continuous to pop-up. Neither the pot nor the fractionating still has this capability.

Then if I solder and fit a 54mm x 54mm x 15mm 2 x 2 x ½ tee to the top of the column just before the offset section and below the reflux return pipe then solder in a 4 x 15mm ½ section of pipe fit a. Vapor phase reflow soldering works on the same idea but Galden boils at a range of temperatures that are useful for soldering. Vapour and Air Permeable Membranes Explained.

Consideration of porous materials such as concrete or masonry should include the ability of these materials to limit moisture and vapor migration into. Multiple-effect water still MWS uses general plant heating steam for heating in the first stage of the process after preheating the feed water by condensers evaporating the pure steam to WFI. Moisture Management in Wall Assemblies.

For product stored in API 650 tanks vapor pressure is typically a partial vapor pressure. Taps into the reflux stream and controls how much is withdrawn. The information in the Departments Vapor Intrusion Technical Guidance Version 50 document is provided free of charge to the public.

The design pressure for an API 650 tank is the pressure exceeding atmospheric that you are designing for. Learn how to make a moonshine or whiskey still. Galden is a completely inert liquid and as.

1213 Vapour emission control system means an arrangement of piping and hoses used to control vapour emissions collected from a tanker and includes the. Hybrid solar still vapour compression refrigeration. The process of mitigating the risk presented by vapours is tried and tested.

The Vapor Management Reflux Still. To prevent against the build-up of vapour pressures or displacement when fuel enters a storage tank the vapour recovery hose will lead to a recovery unit where the vapour will be safely converted back into fuel with any harmless emissions being released back to the atmosphere. Divide the vapor into two flows mechanically.

See illustration below This type of design is difficult to fine tune reflux within the column. However the amount of water vapor transported through vapor diffusion is significantly lower. Design table was created in.

Liquid management The still head does two things. Now to turn it into a vapour management still. In selecting the exterior finish material the design team needs to consider the effects of moisture penetration and vapor and air migration as well as aesthetics to ensure consistency with the design intent.

In general vapour velocity will normally be between 70 to 90 per cent of that which would cause flooding. Calculation of the column diameter is often based on a trial and error approach. We can help you choose the right parts for the type of distillation unit you want to make.

If the vapor pressure is over atmospheric the liquid is boiling and would not be in an API 650 tank. Build your own distiller from our inventory of copper stainless kits and parts. Use your own moonshine still plans.

Perms short for permeability used commonly in North America measured in grainsft2 hinHg.

Reflux Still Designs Explained Part 1 Brewhaus America

The Difference Between Vm Cm And Lm Reflux Stills Managing Reflux Within A Still Learn To Moonshine

Reflux Still Designs Explained Part 1 Brewhaus America

Build A Vapor Management Still With Stilldragon Parts Only Stilldragon Community Forum

The Difference Between Vm Cm And Lm Reflux Stills Managing Reflux Within A Still Learn To Moonshine

Build A Vapor Management Still With Stilldragon Parts Only Stilldragon Community Forum

The Difference Between Vm Cm And Lm Reflux Stills Managing Reflux Within A Still Learn To Moonshine

0 comments

Post a Comment