Remember the access to the hydrant must be an. The strainer shall be fabricated from.

The Case For Inspecting Fire Hydrants Waterworld

In temperate climates where hard freezing is not an issue the most efficient hydrant design is the wet barrel hydrant where valves are located above ground and can be independently controlled.

. The valve is still operated above ground but the valve. It shall be joined with a steel cable or chain and be permanently attached to the dry hydrant head. The Kennedy Valve Guardian Hydrants set the standard for quality in the industry and meets or exceeds all requirements for AWWA C502 latest revision and is UL Listed and FM Approved.

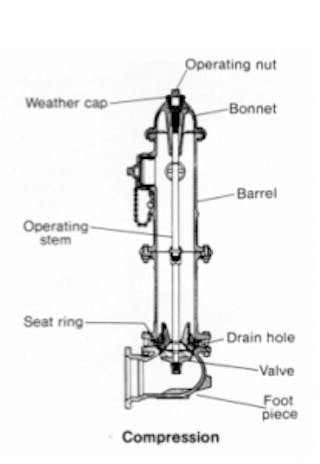

Hydrant elbows hydrant adapter any reducers STRAIGHT PIPE EQUIV. As water supply will usually be the responsibility of the responding mutual aid department it is very important common thread sizes be used to avoid delays. The barrel of the hydrant is drained or pumped dry when the hydrant is not in use and the shut-off valve is located underground.

As a practical matter dry hydrants probably should not be more than 15 feet vertical. With this dry-barrel design the barrel of the hydrant is drained or pumped dry when the hydrant is not in use and the shut-off valve is located underground. Check for the presence of water or ice in the hydrant barrel by use of a plumb bob or other suitable means.

The cap shall be hard plastic or of same metal as NHT connection for maximum corrosion resistance. There is an old saying. Involve the local fire department from planning through construction.

They are the end user and must supply information concerning pumper ability and capacities and the proper size and threads of the riser head to use. The hydrants must receive two coats of field paint. DRY HYDRANT DESIGN A typical dry hydrant drawing is shown on the front cover page.

Open the hydrant SLOWLY approximately 3 to 5 turns allowing time for air to escape from the hydrant barrel through outlet nozzle cap. The cap shall be of snap-onsnap-off design and removable without special tools. Write this figure down on the Design Worksheet at step 3.

Same Day Shipping On All Dry Hydrant Accessories Strainers Caps Plugs. Elevated Ponds Tanks. On the other hand wet barrel hydrants always filled with water from top to bottom.

This can be used to determine how much water will be available from your dry hydrant. To do this one must adapt the Dry Hydrant concept to fit local needs whatever they may be. The paint color must be as follows.

Based on the Guardian K81-D design the K81-DD is easy to install maintain and repair. Ad Female Male Dry Fire Hydrants. WETPLUG Dry Hydrants are designed for high performance and easy to install maintain and repair.

Recommendations for the proper design and installation of dry hydrants. Replace the outlet nozzle cap. Dry Barrel Hydrant Design.

Dry Hydrant A pipe with a threaded connection that allows fire apparatus to. The hydrant above the ground line must be thoroughly cleaned all rust removed and the existing paint scuffed for overcoating. Dry Hydrant Design Solutions Menu.

Excellent and proven flow characteristics. This standard pertains to dry-barrel fire hydrants that are intended for use in water supply systems in all climates including those where freezing temperatures occur. Add the numbers from step 1 and step 2 together to obtain the TOTAL STRAIGHT PIPE EQUIVALENT of the hydrant.

Write this down on the worksheet at step 2. Heres no water left above ground after the hydrant has been used so the hydrant is safe from freezing in cold regions. The trick is to figure out how to make it usable for fighting fires.

Dry barrel hydrant design And here arrives quite possibly the most awaited killing manicure with long device guns all on the nails. The K81-DD utilizes a light weight ductile iron upper barrel to allow for a single man repair. A successful Dry Hydrant program will be designed with the future growth of your fire department in mind ie 5-10 years and 1000 - 1500 gpm pumper trucks.

The department risks losing suction due to leaks from pump seals and or hydrant fittings. Geographically speaking dry barrel hydrants are commonly used in the cold regions because their underground valves ensure that no water will be left above ground thus preventing themselves from freezing or breaking. Wet-barrel fire hydrants which are intended for use only in areas where the climate is mild and freezing temperatures do not occur are covered in ANSI.

The field paint must be applied by brush. The field paint must be a quick drying enamel. What is the Difference Between a Wet Barrel and Dry Barrel Hydrant.

Dry barrel design eliminates damage to the hydrant caused by freezing of the upper part. A complete line of dry barrel hydrants designed for high flows and low maintenance. As a critical piece of any emergency response system used to preserve lives and property all Mueller fire hydrants are designed built and tested to assure high performance long life and dependability.

Breaking System provided to protect against mechanical damages. Dry Barrel Hydrant A municipal type hydrant that allows for access to a piped water system under pressure but allows for the riser barrel to remain dry with the operation of a valve below the frost line. The solution is simply to keep the water underground below the ground freezing level so that even in the winter the water is liquid and does not turn to ice.

Modern style dry barrel The series 27 hydrant is our dry barrel fire hydrant meeting or exceeding the requirements of AWWA C502 and is ULULC listed and FM approved. Numerous dry and wet barrel designs are available that meet stringent ULFM requirements some with maximum working pressures of 350psi. In colder climates dry barrel hydrants will be required which use a single operating valve that is located below ground in the base of the riser and which charge all outlets simultaneously when.

Leave it loose enough to allow air to escape. Available In Straight 90 and 45 Degrees. Designs Innovations and Use of Dry Hydrants.

Gainedt youre keen on to tease your friends and frighten your enemies with this Creative 3d Nail Art Images.

Rapidrop British Manufacturer Supplier Of Fire Sprinklers Fire Suppression Equipment

Series 27 Dry Barrel Fire Hydrants American Avk

Breaking Down Components Of A Fire Hydrant

Breaking Down Components Of A Fire Hydrant

0 comments

Post a Comment